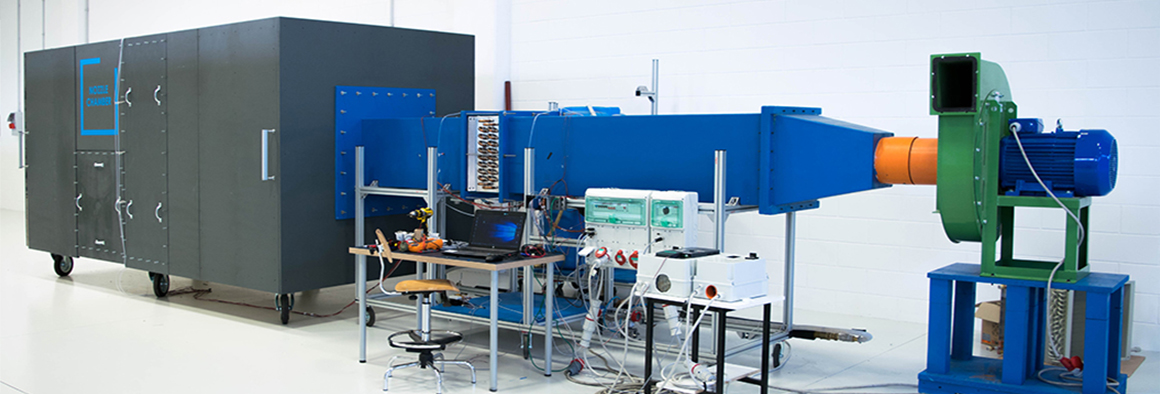

Enthalpy tunnel

The enthalpy tunnel installed within the Advantech TIME laboratory makes it possible to characterize heat exchangers according to the UNI EN ISO 1216 standard. The explorable work conditions are sufficiently ample to allow its application to many types of exchangers, such as those used for static evaporators, condensers, dry coolers, water/oil coolers…

Measurement and uses

The enthalpy tunnel is made of a closed circuit where it is possible to measure air flow rate, by keeping under control its humidity and temperature at the levels required by each specific test. The heat exchanger, with a maximum size of 500*500 mm, can be powered by water or a mixture of water and glycol, extending the temperature measurement range between -5°C and +80°C. Maximum measurable power is 35kW, both in air heating and cooling. It can be used to test:

- finned coils

- compact exchangers in cross flow

- also with dehumidification (measuring condensate)

The nozzle chamber, used to measure air flow rate up to 60,000 m3/h is an integral part of the tunnel. Thanks to its dimensional characteristics, the chamber can be used on its own to measure the performance of axial fans with a diameter of up to 800 mm and in accordance to the UNI EN ISO 5801 standard.

For example, it was used in this project:

Oesse – design process optimization for custom heat exchangers